Corrocoat has been providing cost effective anti corrosion methods, materials and engineering rehabilitation expertise for over 30 years and enjoys a proven track record in solving corrosion-related problems throughout industry, operating successfully across five continents from more than thirty locations worldwide.

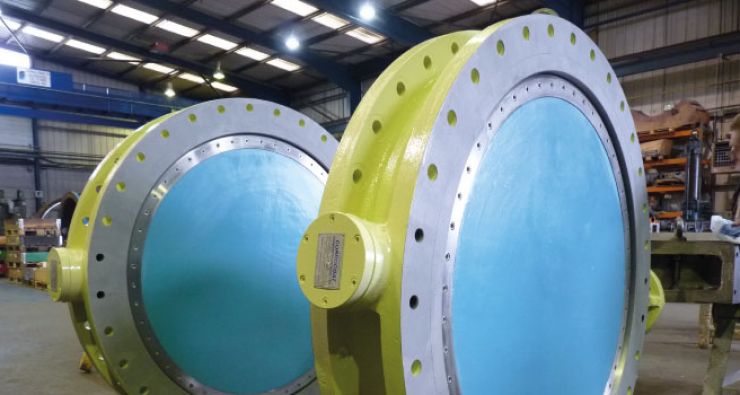

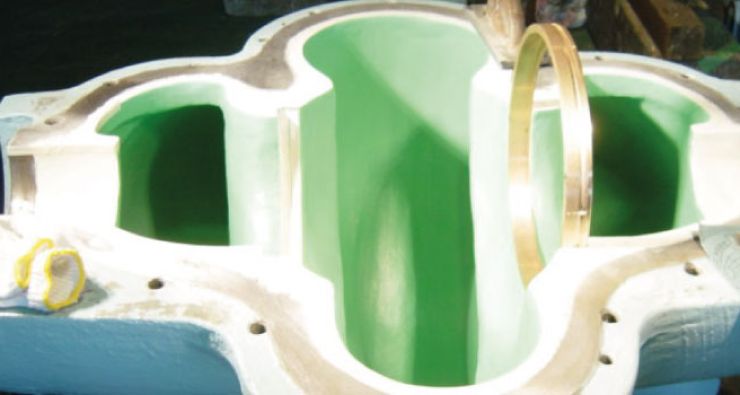

Manufacturing glassflake coatings tailored to meet the demands of specific environments and problems, we offer comprehensive repair, corrosion protection, prevention, and maintenance solutions, with the flexibility to respond swiftly and positively to individual client requirements.

Corrocoat technical solutions combine advanced corrosion engineering skills and solid technical expertise with total commitment to quality and performance.

Whether you simply want to purchase corrosion protection coatings, have us manufacture spares, new equipment or carry out a turn key project

- more than 30 years of development cost effective materials with applications worldwide

- in Corrocoat produced unique technology of Advanced Glassflake

- licenced partners and overseas operations Corrocoat in more than 35 countries all around The World

- more than 70 applications for aggressive, corrosive and stressed environment

- long term and cost effective anti-corrosion protection

- extending lifetime of current assets – refurbishment of cavitation, perforation, pitting corrosion

- maintenance – storage tanks, vessels, pumps, pipelines, transporting vessels, floors etc.

During a period of time from 2009 CORROCOAT EGYPT supply and apply projects provided for our clients in case they face corrosion problems. You can also read our Case Study – technical solution and work process some examples are published here.

Whether you simply want to purchase corrosion protection coatings, have us manufacture spares, new equipment or carry out a turn key project.

Serving Industry…

- Petrochemical, Oil & Gas

- Energetics Industry

- Paper & cellulose Industry

- Food & Agriculture Industry

- Structural Steel Industry

- Mining Industry

- Water Treatment & Processing

- Marine & Port Sector

…Where EVER corrosion occurS.

- X-Ray radiography testing.

- Ultrasonic testing.

- Magnetic particles testing.

- Liquid penetrant testing.

- Provision of welding inspectors & quality control engineers, preparing all kinds of inspections procedures.

- Metals and fabricated metals receiving and inspection.